Get Quote Now!

Welcome to discuss your purchasing requirements with our customer service.

Three-side full seal structure: ultrasonic welding or hot press sealing technology to ensure the bag body is completely sealed, effectively protect the flowers from moisture loss and extend the freshness period.

Ventilation hole customization: optional automatic punching function, pre-set ventilation holes in the bag body, balancing humidity and ventilation, suitable for fresh flowers, green plants and other fresh packaging.

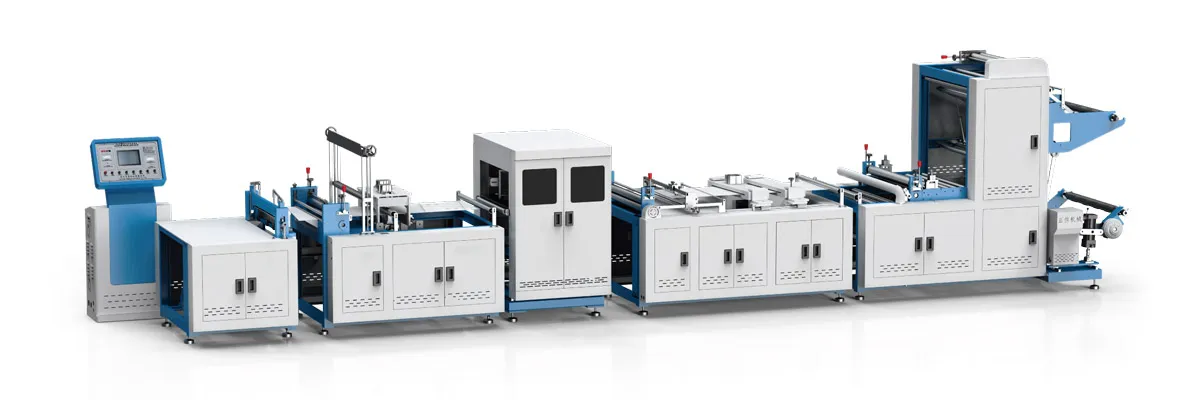

One-touch operation: the whole process from feeding, folding, sealing to cutting is automated, the production speed can reach 80~120 pcs/min, the efficiency is more than 5 times higher than manual.

Intelligent deviation correction system: automatically calibrate the material position to ensure that the printing pattern is aligned with the sealing edge, reducing the scrap rate.

Multi-size compatibility: Different sizes of bags (height 20cm~50cm) can be produced through quick mold change to meet the needs of single bouquets, flower baskets and other packaging needs.

Environmentally friendly process: no glue and no needle and thread, in line with food-grade packaging standards, supporting biodegradable non-woven materials.

Florist flower packaging, gift bouquets, wedding decorations and so on. Support customized carry handles, window lamination, etc.

| Model | ZXL-1800 |

| Max Fabic Roll Width | 700mm |

| Production Speed | 100-140pcs/min |

| Bag Height | 100-380mm |

| Bag Width | 200-700mm |

| Material Thickness | 20-80g/㎡ |

| Voltage | 220V |

| Total Power | 15kw |

| Overall Dimension(L*W*H) | 10100*1300*2050mm |

Welcome to discuss your purchasing requirements with our customer service.

Always customer-oriented and create value for customers

A: Within one week after machine arrival your factory.

A: We will finish installation and training within 15 days.

A: You should charge for the cost of our engineer’s visa , air tickets, hotel, food ,and also their salary 80USD one day per person.

A: All our machine have one year guarantee, starting from finished installation.

A: We also can do service for you, but you need pay salary for my technician 80USD/day.

A: We would express the free replacement parts during the warranty date.

A: Our engineer understand a little English. All our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

A: Of course, we will check and inform you as soon as possible.

A: Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our sales at any time. Our engineer will take a solution video according your description.

A: Except Two for bag making machine, flexo printing, slitting, ultrasonic sewing, hydraulic punching machine only need one person for each.

Welcome to discuss your purchasing requirements with our customer service.