Always customer-oriented and create value for customers

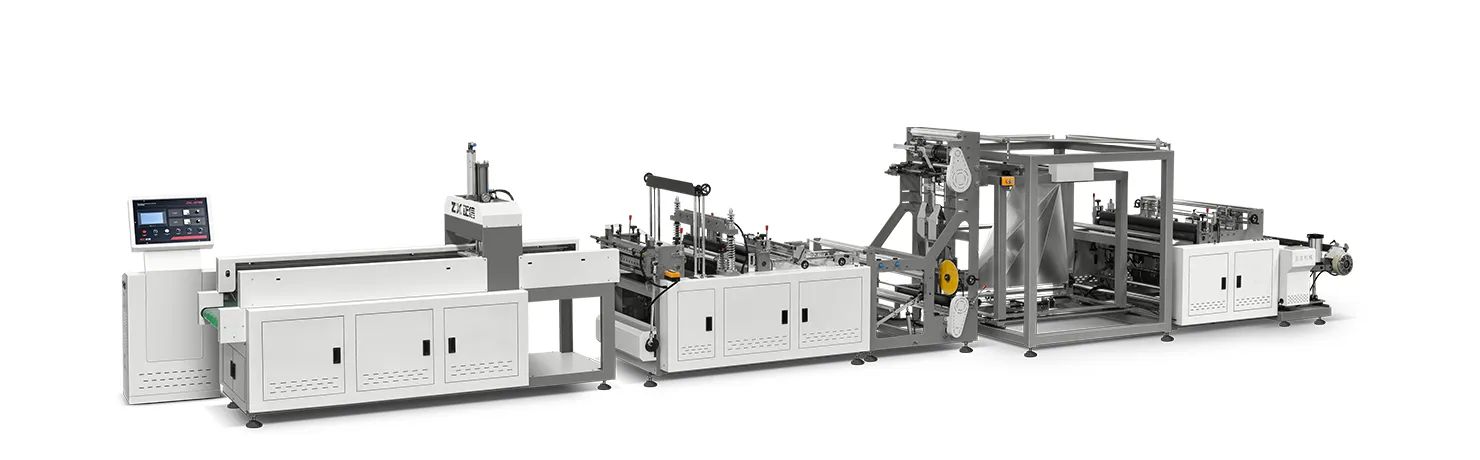

Function: Automatic loading, magnetic power tension controller, Automatic correcting deviation system.

Function: Fold part can adjust, One side one ultrasonic part

Brand: Ounuo

This Part have two ultrasonic which would keep working when you making all kind of bag except T-shirt bag.

Function: This part is for fabric fold, for different type bag making, the pull through way is different.

Our engineer would teach you the way when machine install

Function: For box bag, handle bag, D-cut bag making, this part is for bag bottom finish. For T-shirt bag making, this part is for bag side gusset finish.

This Part have one ultrasonic which would working when you making T-shirt bag.

Function: This part is for the picture check on the non woven fabric to ensure your bag making accurate.

Allwell Bag Making Machine would stop if the check eye miss the picture.

Function: Using Ounuo made ultrasonic to seal bag side.

Different width bag making machine, the ultrasonic is different.

700 model have two ultrasonic;

800 model have three ultrasonic.

Function: Cutting the bag one by one and collect, then pack these goods.

Name: Touch Screen, PLC

Brand: VENINEW

Original: TAIWAN

A: Within one week after machine arrival your factory.

A: We will finish installation and training within 15 days.

A: You should charge for the cost of our engineer’s visa , air tickets, hotel, food ,and also their salary 80USD one day per person.

A: All our machine have one year guarantee, starting from finished installation.

A: We also can do service for you, but you need pay salary for my technician 80USD/day.

A: We would express the free replacement parts during the warranty date.

A: Our engineer understand a little English. All our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

A: Of course, we will check and inform you as soon as possible.

A: Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our sales at any time. Our engineer will take a solution video according your description.

A: Except Two for bag making machine, flexo printing, slitting, ultrasonic sewing, hydraulic punching machine only need one person for each.

Welcome to discuss your purchasing requirements with our customer service.